Casing & Tubing

Home / Casing & Tubing

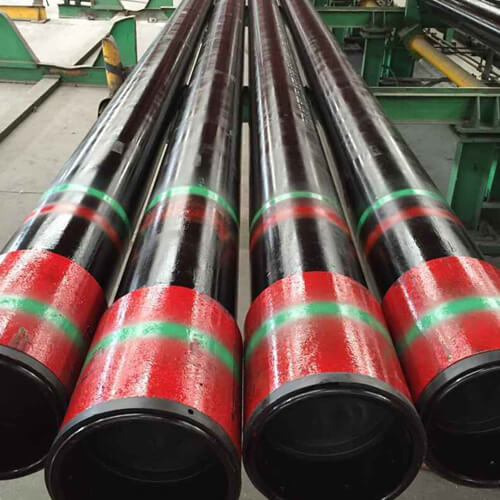

ZhiSheng Pipe offers a complete range of API 5CT casing and tubing for all types of oil exploration and production demands. The material includes carbon steel (for the most common use), alloy, chrome and high alloy steels. API 5CT grades cover J55 / K55, N80 type 1 and N80Q, L80, C90, T95, P110, Q125, and with additional requirements of 13 Cr.

Supply Range

Casing Size: OD: 4-1/2″ – 20″ (114.3 mm – 508 mm)

Tubing Size: OD: 2-3/8″ – 4-1/2″ (60.3 mm – 114.3 mm)

Length: R1 (4.88 m – 7.62 m), R2 (7.62 m – 10.36 m), R3 (10.36 m – longer)

Standard: API 5CT, JIS G3439, BS EN ISO 11960, NF M87-207

Material: H40, J55, K55, N80, L80, C90, T95, P110, Q125, 13Cr

Type of connections for Casing: BTC (thread coupling buttress), LTC (long round thread coupling), premium connection.

Types of connections for Tubing: BTC, NUE, EUE, Premium

Usage: Conveying gas, water, oil, natural gas

Premium connections

Premium connections that replace the connections VAM TOP, NEW VAM, HYDRIL CS, TPCQ (TPCO), HSM-1/HSM-2 (Hengyang Valin Connections), and etc.

API 5CT is applicable to following connections which complied with API SPEC 5B:

• SC: Short round thread casing

• LC: Long ound thread casing

• BC: Buttress thread casing

• NU: Non-upset tubing

• EU: External upset tubing

• IJ: Integral tubing connections

The most common API tubing specifications are listed here. Others steel grades, nominal weights, and connections are available on request.

Label | OD (mm) | WT (mm) | Type of End-finish | |||||||||

NU T&C | EU T&C | IJ | H40 | J55 | L80 | N80 | C90 | T95 | P110 | |||

1.9 | 2.75 | 2.9 | 2.76 | 48.26 | 3.68 | PNUI | PNUI | PNUI | PNUI | PNUI | PNUI | – |

1.9 | 3.65 | 3.73 | – | 48.26 | 5.08 | PU | PU | PU | PU | PU | PU | PU |

1.9 | 4.42 | – | – | 48.26 | 6.35 | – | – | P | – | P | P | – |

2 3/8 | 4 | – | – | 60.32 | 4.24 | PU | PN | PN | PN | PN | PN | – |

2 3/8 | 4.6 | 4.7 | – | 60.32 | 4.83 | PNU | PNU | PNU | PNU | PNU | PNU | PNU |

2 3/8 | 5.8 | 5.95 | – | 60.32 | 6.45 | – | – | PNU | PNU | PNU | PNU | PNU |

2 3/8 | 6.6 | – | – | 60.32 | 7.49 | – | – | P | – | P | P | – |

2 3/8 | 7.35 | 7.45 | – | 60.32 | 8.53 | – | – | PU | – | PU | PU | – |

2 7/8 | 6.4 | 6.5 | – | 73.02 | 5.51 | PNU | PNU | PNU | PNU | PNU | PNU | PNU |

2 7/8 | 7.8 | 7.9 | – | 73.02 | 7.01 | – | – | PNU | PNU | PNU | PNU | PNU |

2 7/8 | 8.6 | 8.7 | – | 73.02 | 7.82 | – | – | PNU | PNU | PNU | PNU | PNU |

2 7/8 | 9.35 | 9.45 | – | 73.02 | 8.64 | – | – | PU | – | PU | PU | – |

2 7/8 | 10.5 | – | – | 73.02 | 9.96 | – | – | P | – | P | P | – |

3 1/2 | 7.7 | – | – | 88.9 | 5.49 | PN | PN | PN | PN | PN | PN | – |

3 1/2 | 9.2 | 9.3 | – | 88.9 | 6.45 | PNU | PNU | PNU | PNU | PNU | PNU | PNU |

3 1/2 | 10.2 | – | – | 88.9 | 7.34 | PN | PN | PN | PN | PN | PN | – |

3 1/2 | 12.7 | 12.95 | – | 88.9 | 9.52 | – | – | PNU | PNU | PNU | PNU | PNU |

3 1/2 | 14.3 | – | – | 88.9 | 10.92 | – | – | P | – | P | P | – |

3 1/2 | 15.5 | – | – | 88.9 | 12.09 | – | – | P | – | P | P | – |

4 | 9.5 | – | – | 101.6 | 5.74 | PN | PN | PN | PN | PN | PN | – |

4 | 10.7 | 11 | – | 101.6 | 6.65 | PU | PU | PU | PU | PU | PU | – |

4 | 13.2 | – | – | 101.6 | 8.38 | – | – | P | – | P | P | – |

4 | 16.1 | – | – | 101.6 | 10.54 | – | – | P | – | P | P | – |

4 1/2 | 12.6 | 12.75 | – | 114.3 | 6.88 | PNU | PNU | PNU | PNU | PNU | PNU | – |

4 1/2 | 15.2 | – | – | 114.3 | 8.56 | – | – | P | – | P | P | – |

Mechanical Properties

Standard | Steel Grade | Tensile Strength(MPa) | Yield Strength(MPa) | Elongation(%) | Hardness |

API SPEC 5CT | J55 | ≥517 | 379~552 | 0.5% | |

K55 | ≥655 | 379~552 | 0.5% | ||

N80 | ≥689 | 552~758 | 0.5% | ||

L80(13Cr) | ≥655 | 552~655 | 0.5% | ≤241HB | |

P110 | ≥862 | 758~965 | 0.6% |

Chemical Compositions(%)

Standard | Steel Grade | Chemical Compositions(%) | ||||||||||

C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V | Als | ||

API SPEC 5CT | J55 | 0.34~0.39 | 0.20~0.35 | 1.25~1.50 | ≤0.020 | ≤0.015 | ≤0.15 | ≤0.20 | ≤0.20 | / | / | ≤0.020 |

K55 | 0.34~0.39 | 0.20~0.35 | 1.25~1.50 | ≤0.020 | ≤0.015 | ≤0.15 | ≤0.20 | ≤0.20 | / | / | ≤0.020 | |

N80 | 0.34~0.38 | 0.20~0.35 | 1.45~1.70 | ≤0.020 | ≤0.015 | ≤0.15 | / | / | / | 0.11~0.16 | ≤0.020 | |

L80(13Cr) | 0.15~0.22 | ≤1.00 | 0.25~1.00 | ≤0.020 | ≤0.010 | 12.0~14.0 | ≤0.20 | ≤0.20 | / | / | ≤0.020 | |

P110 | 0.26~0.35 | 0.17~0.37 | 0.40~0.70 | ≤0.020 | ≤0.010 | 0.80~1.10 | ≤0.20 | ≤0.20 | 0.15~0.25 | ≤0.08 | ≤0.020

| |

API Casing Specifications

|

Labels |

Outside diameter D |

Nominal linear mass T&C |

Wall thickness t |

J55 |

N80 |

L80 |

C90 |

P110 |

Q125 |

|

|

mm |

kg/m |

mm |

K55 |

– |

T95 |

|||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

|

4 1/2 |

9.5 |

114.3 |

14.14 |

5.21 |

PS |

– |

– |

– |

– |

– |

|

4 1/2 |

10.5 |

114.3 |

15.63 |

5.69 |

PSB |

– |

– |

– |

– |

– |

|

4 1/2 |

11.6 |

114.3 |

17.26 |

6.35 |

PSLB |

PLB |

PLB |

PLB |

PLB |

– |

|

4 1/2 |

13.5 |

114.3 |

20.09 |

7.37 |

– |

PLB |

PLB |

PLB |

PLB |

– |

|

4 1/2 |

15.1 |

114.3 |

22.47 |

8.56 |

– |

– |

– |

– |

PLB |

PLB |

|

5 |

11.5 |

127 |

17.11 |

5.59 |

PS |

– |

– |

– |

– |

– |

|

5 |

13 |

127 |

19.35 |

6.43 |

PSLB |

– |

– |

– |

– |

– |

|

5 |

15 |

127 |

22.32 |

7.52 |

PSLBE |

PLBE |

PLBE |

PLBE |

PLBE |

– |

|

5 |

18 |

127 |

26.79 |

9.19 |

– |

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

|

5 |

21.4 |

127 |

31.85 |

11.1 |

– |

PLB |

PLB |

PLB |

PLB |

PLB |

|

5 |

23.2 |

127 |

34.53 |

12.14 |

– |

PLB |

PLB |

PLB |

PLB |

PLB |

|

5 |

24.1 |

127 |

35.86 |

12.7 |

– |

PLB |

PLB |

PLB |

PLB |

PLB |

|

5 1/2 |

14 |

139.7 |

20.83 |

6.2 |

PS |

– |

– |

– |

– |

– |

|

5 1/2 |

15.5 |

139.7 |

23.07 |

6.98 |

PSLBE |

– |

– |

– |

– |

– |

|

5 1/2 |

17 |

139.7 |

25.3 |

7.72 |

PSLBE |

PLBE |

PLBE |

PLBE |

PLBE |

– |

|

5 1/2 |

20 |

139.7 |

29.76 |

9.17 |

– |

PLBE |

PLBE |

PLBE |

PLBE |

– |

|

5 1/2 |

23 |

139.7 |

34.23 |

10.54 |

– |

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

|

5 1/2 |

26.8 |

139.7 |

39.88 |

12.7 |

– |

– |

– |

P |

– |

– |

|

5 1/2 |

29.7 |

139.7 |

44.2 |

14.27 |

– |

– |

– |

P |

– |

– |

|

5 1/2 |

32.6 |

139.7 |

48.51 |

15.88 |

– |

– |

– |

P |

– |

– |

|

5 1/2 |

35.3 |

139.7 |

52.53 |

17.45 |

– |

– |

– |

P |

– |

– |

|

5 1/2 |

38 |

139.7 |

56.55 |

19.05 |

– |

– |

– |

P |

– |

– |

|

5 1/2 |

40.5 |

139.7 |

60.27 |

20.62 |

– |

– |

– |

P |

– |

– |

|

5 1/2 |

43.1 |

139.7 |

64.14 |

22.22 |

– |

– |

– |

P |

– |

– |

|

6 5/8 |

20 |

168.28 |

29.76 |

7.32 |

PSLB |

– |

– |

– |

– |

– |

|

6 5/8 |

24 |

168.28 |

35.72 |

8.94 |

PSLBE |

PLBE |

PLBE |

PLBE |

PLBE |

– |

|

6 5/8 |

28 |

168.28 |

41.67 |

10.59 |

– |

PLBE |

PLBE |

PLBE |

PLBE |

– |

|

6 5/8 |

32 |

168.28 |

47.62 |

12.06 |

– |

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

|

7 |

17 |

177.8 |

25.3 |

5.87 |

– |

– |

– |

– |

– |

– |

|

7 |

20 |

177.8 |

29.76 |

6.91 |

PS |

– |

– |

– |

– |

– |

|

7 |

23 |

177.8 |

34.23 |

8.05 |

PSLBE |

PLBE |

PLBE |

PLBE |

– |

– |

|

7 |

26 |

177.8 |

38.69 |

9.19 |

PSLBE |

PLBE |

PLBE |

PLBE |

PLBE |

– |

|

7 |

29 |

177.8 |

43.16 |

10.36 |

– |

PLBE |

PLBE |

PLBE |

PLBE |

– |

|

7 |

32 |

177.8 |

47.62 |

11.51 |

– |

PLBE |

PLBE |

PLBE |

PLBE |

– |

|

7 |

35 |

177.8 |

52.09 |

12.65 |

– |

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

|

7 |

38 |

177.8 |

56.55 |

13.72 |

– |

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

|

7 |

42.7 |

177.8 |

63.54 |

15.88 |

– |

– |

– |

P |

– |

– |

|

7 |

46.4 |

177.8 |

69.05 |

17.45 |

– |

– |

– |

P |

– |

– |

|

7 |

50 |

177.8 |

74.56 |

19.05 |

– |

– |

– |

P |

– |

– |

|

7 |

53.6 |

177.8 |

79.77 |

20.62 |

– |

– |

– |

P |

– |

– |

|

7 |

57.1 |

177.8 |

84.97 |

22.22 |

– |

– |

– |

P |

– |

– |

|

7 5/8 |

24 |

193.68 |

35.72 |

7.62 |

– |

– |

– |

– |

– |

– |

|

7 5/8 |

26.4 |

193.68 |

39.29 |

8.33 |

PSLBE |

PLBE |

PLBE |

PLBE |

– |

– |

|

7 5/8 |

29.7 |

193.68 |

44.2 |

9.52 |

– |

PLBE |

PLBE |

PLBE |

PLBE |

– |

|

7 5/8 |

33.7 |

193.68 |

50.15 |

10.92 |

– |

PLBE |

PLBE |

PLBE |

PLBE |

– |

|

7 5/8 |

39 |

193.68 |

58.04 |

12.7 |

– |

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

|

7 5/8 |

42.8 |

193.68 |

63.69 |

14.27 |

– |

PLB |

PLB |

PLB |

PLB |

PLB |

|

7 5/8 |

45.3 |

193.68 |

67.41 |

15.11 |

– |

PLB |

PLB |

PLB |

PLB |

PLB |

|

7 5/8 |

47.1 |

193.68 |

70.09 |

15.88 |

– |

PLB |

PLB |

PLB |

PLB |

PLB |

|

7 5/8 |

51 |

193.68 |

76.19 |

17.45 |

– |

– |

– |

P |

– |

– |

|

7 5/8 |

55.3 |

193.68 |

82.3 |

19.05 |

– |

– |

– |

P |

– |

– |

|

8 5/8 |

24 |

219.08 |

35.72 |

6.71 |

PS |

– |

– |

– |

– |

– |

|

8 5/8 |

28 |

219.08 |

41.67 |

7.72 |

– |

– |

– |

– |

– |

– |

|

8 5/8 |

32 |

219.08 |

47.62 |

8.94 |

PSLBE |

– |

– |

– |

– |

– |

|

8 5/8 |

36 |

219.08 |

53.57 |

10.16 |

PSLBE |

PLBE |

PLBE |

PLBE |

– |

– |

|

8 5/8 |

40 |

219.08 |

59.53 |

11.43 |

– |

PLBE |

PLBE |

PLBE |

PLBE |

– |

|

8 5/8 |

44 |

219.08 |

65.48 |

12.7 |

– |

PLBE |

PLBE |

PLBE |

PLBE |

|

|

8 5/8 |

49 |

219.08 |

72.92 |

14.15 |

– |

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

|

9 5/8 |

32 |

244.48 |

48.07 |

7.92 |

– |

– |

– |

– |

– |

– |

|

9 5/8 |

36 |

244.48 |

53.57 |

8.94 |

PSLB |

– |

– |

– |

– |

– |

|

9 5/8 |

40 |

244.48 |

59.53 |

10.03 |

PSLBE |

PLBE |

PLBE |

PLBE |

– |

– |

|

9 5/8 |

43.5 |

244.48 |

64.73 |

11.05 |

– |

PLBE |

PLBE |

PLBE |

PLBE |

– |

|

9 5/8 |

47 |

244.48 |

69.94 |

11.99 |

– |

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

|

9 5/8 |

53.5 |

244.48 |

79.62 |

13.84 |

– |

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

|

9 5/8 |

58.4 |

244.48 |

86.91 |

15.11 |

– |

PLB |

PLB |

PLB |

PLB |

PLB |

|

9 5/8 |

59 |

244.48 |

88.4 |

15.47 |

– |

– |

– |

P |

– |

– |

|

9 5/8 |

64.9 |

244.48 |

96.58 |

17.07 |

– |

– |

– |

P |

– |

– |

|

9 5/8 |

70.3 |

244.48 |

104.62 |

18.64 |

– |

– |

– |

P |

– |

– |

|

9 5/8 |

75.6 |

244.48 |

112.5 |

20.24 |

– |

– |

– |

P |

– |

– |

|

10 3/4 |

32.75 |

273.05 |

48.74 |

7.09 |

– |

– |

– |

– |

– |

– |

|

10 3/4 |

40.5 |

273.05 |

60.27 |

8.89 |

PSB |

– |

– |

– |

– |

– |

|

10 3/4 |

45.5 |

273.05 |

67.71 |

10.16 |

PSBE |

– |

– |

– |

– |

– |

|

10 3/4 |

51 |

273.05 |

75.9 |

11.43 |

PSBE |

PSBE |

PSBE |

PSBE |

PSBE |

– |

|

10 3/4 |

55 |

273.05 |

82.59 |

12.57 |

– |

PSBE |

PSBE |

PSBE |

PSBE |

– |

|

10 3/4 |

60.7 |

273.05 |

90.33 |

13.84 |

– |

– |

– |

PSBE |

PSBE |

PSBE |

|

10 3/4 |

65.7 |

273.05 |

97.77 |

15.11 |

– |

– |

– |

PSB |

PSB |

PSB |

|

10 3/4 |

73.2 |

273.05 |

108.93 |

17.07 |

– |

– |

– |

P |

– |

– |

|

10 3/4 |

79.2 |

273.05 |

117.86 |

18.64 |

– |

– |

– |

P |

– |

– |

|

10 3/4 |

85.3 |

273.05 |

126.94 |

20.24 |

P |

|||||

|

11 3/4 |

42 |

298.45 |

62.5 |

8.46 |

– |

– |

– |

– |

– |

– |

|

11 3/4 |

47 |

298.45 |

69.94 |

9.53 |

PSB |

– |

– |

– |

– |

– |

|

11 3/4 |

54 |

298.45 |

80.36 |

11.05 |

PSB |

– |

– |

– |

– |

– |

|

11 3/4 |

60 |

298.45 |

89.29 |

12.42 |

PSB |

PSB |

PSB |

PSB |

PSB |

PSB |

|

11 3/4 |

65 |

298.45 |

96.73 |

13.56 |

– |

P |

P |

P |

P |

P |

|

11 3/4 |

71 |

298.45 |

105.66 |

14.78 |

– |

P |

P |

P |

P |

P |

|

13 3/8 |

48 |

339.72 |

71.43 |

8.38 |

– |

– |

– |

– |

– |

– |

|

13 3/8 |

54.5 |

339.72 |

81.1 |

9.65 |

PSB |

– |

– |

– |

– |

– |

|

13 3/8 |

61 |

339.72 |

90.78 |

10.92 |

PSB |

– |

– |

– |

– |

– |

|

13 3/8 |

68 |

339.72 |

101.19 |

12.19 |

PSB |

PSB |

PSB |

PSB |

PSB |

– |

|

13 3/8 |

72 |

339.72 |

107.15 |

13.06 |

– |

PSB |

PSB |

PSB |

PSB |

PSB |

|

16 |

65 |

406.4 |

96.73 |

9.53 |

– |

– |

– |

– |

– |

– |

|

16 |

75 |

406.4 |

111.61 |

11.13 |

PSB |

– |

– |

– |

– |

– |

|

16 |

84 |

406.4 |

125.01 |

12.57 |

PSB |

– |

– |

– |

– |

– |

|

16 |

109 |

406.4 |

162.21 |

16.66 |

P |

P |

P |

– |

P |

P |

|

18 5/8 |

87.5 |

473.08 |

130.21 |

11.05 |

PSB |

– |

– |

– |

– |

– |

|

20 |

94 |

508 |

139.89 |

11.13 |

PSLB |

– |

– |

– |

– |

– |

|

20 |

106.5 |

508 |

158.49 |

12.7 |

PSLB |

– |

– |

– |

– |

– |

|

20 |

133 |

508 |

197.93 |

16.13 |

PSLB |

– |

– |

– |

– |

– |

|

P——Plain end; S——Short round thread;L——Long round thread;B——Buttress thread;E——Extreme line. |

||||||||||

- We aim to deliver an unprecedented selection of piping & tubing products with the best service and supply chain in the world.

- Phone: +86 151-9716-2285

- Email: sales@zhishengpipe.com

- Add: No. 68, Qinglan Road, Xinhe Street, Kaifu District, Changsha City, Hunan, China

Services

- Customized Pipe Solutions

- Pipe Threading

- CUT-TO-LENGTH

- CUT & ROLL GROOVING

- Pipe Beveling

- Pipe Coatings

- Slotting and Perforating

Inquiry Now

© 2009 – 2024 ZhiSheng Industries Co,.Ltd. All Rights Reserved.